TLIMS Limit Set Definition

A Limit Set is a specific configuration for defining the confines of a perceived value. In TLIMS, a Limit Set describes what is most commonly observed as Specifications or Control Limits however TLIMS has specific designations for a Limit Set.

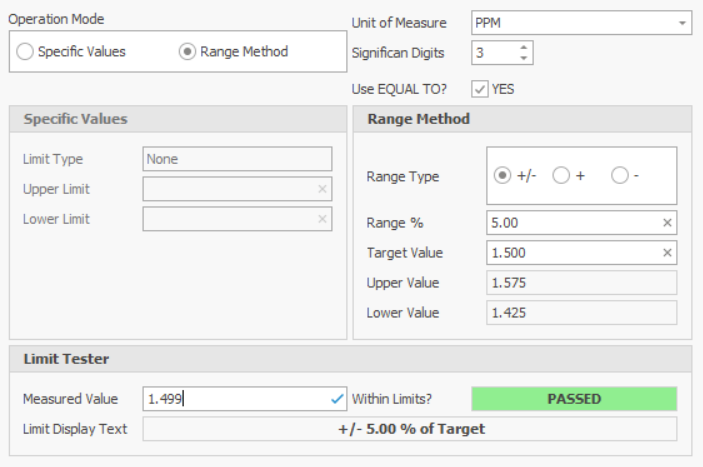

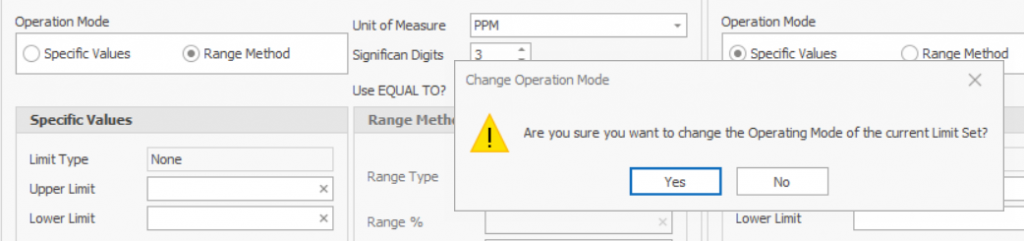

The Limit Set editor supports both Specific Values and Range Values.

Specific Values – will have definitions for Upper and Lower (Between), Upper Only (Max Allowed), Lower Only (Min Allowed).

Range Values – will have definitions for a Target Value and then a Range Percentage value – the limit set is self calculating to determine the upper and lower ranges.

+/- indicates determine if the value range is both upper and lower.

– indicates target to lower value

+ indicates target to upper value

UseEqualTo is a flag that will allow values to be equal to the specified limits.

Specifications vs Control Limits

- Spec Limits, official set specifications to adhere to. Overall limits that designate what is acceptable and unacceptable.

- Control Limits, another level of limits on a product that supports streamlining processes and making them stable.

Commercial vs Process Limits

TLIMS has 2 designations of control limits: Commercial and Process.

- Commercial Limits, a type of control limit set externally (or customer imposed) process limits that may also be enforced.

- Process Limits, a type of control limit calculated and set internally and defined by the actual manufacturing process.

OOS vs OOC Designation

OOS vs. OOC: Out of Spec designates that a final product has violated specification and may be unacceptable to ship, whereas Out of Control designates that a product needs further investigation but could be acceptable.

Ship To Control (S2C)

Ship to Control is a process/program that some clients elect to have notification and approvals when out of control conditions occur. The OOC Approval process allows documentation of the approval/rejection of the final product.